Durability of Asphalt and the Role of Rhinophalt Preservation

The Importance of Air Voids in Asphalt Pavements

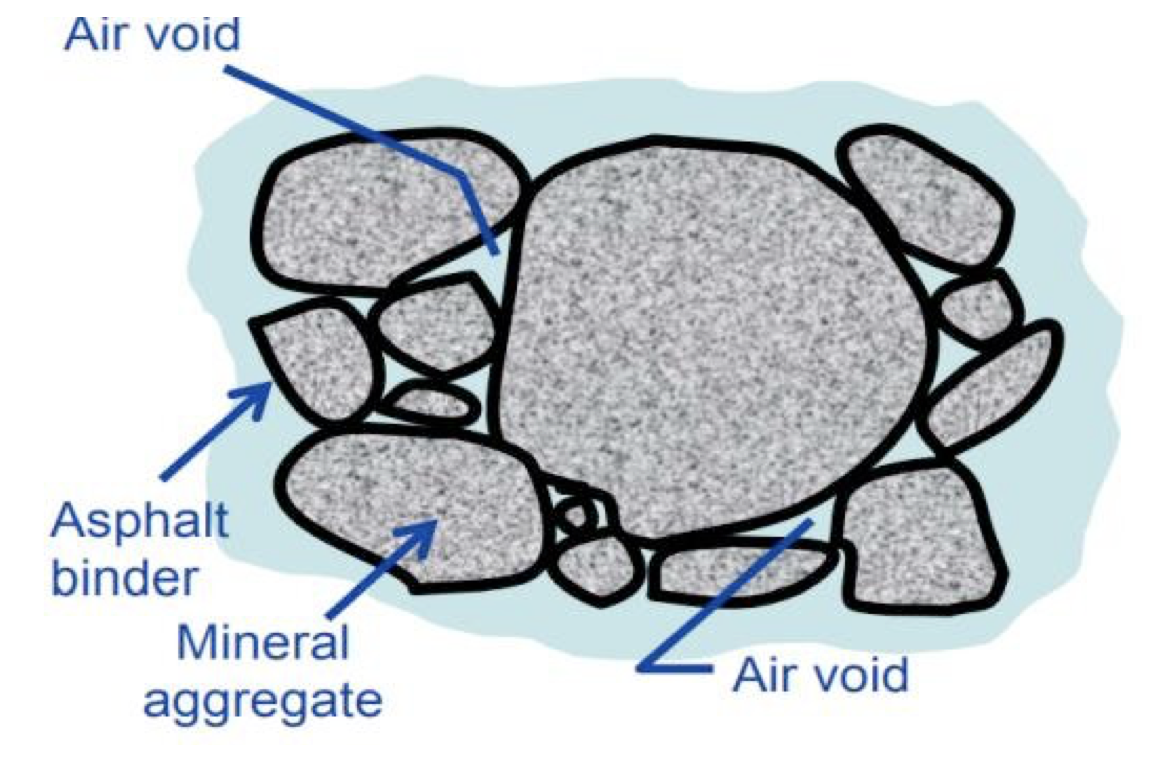

Air voids play a critical role in determining the long-term performance and durability of flexible asphalt pavements. They represent the small, interconnected spaces within the compacted mixture that are not filled by aggregate or bitumen. While some air voids are necessary to allow for binder expansion, temperature movement and traffic-induced densification – excessive or uneven air void content can have a major impact on pavement life.

The air void content directly influences stiffness, permeability, deformation resistance, fatigue life and susceptibility to oxidation and moisture damage. If voids are too low, the mix can become over-dense and prone to bleeding or plastic deformation. Conversely, if the air void content is too high, the mixture becomes more permeable, allowing air and water to penetrate the surface layer and accelerate oxidative ageing and binder hardening. This increased permeability leads to premature cracking, ravelling and a loss of waterproofing, all of which reduce the pavement’s service life.

Excessive in-situ air voids, particularly when interconnected, further amplify these effects by providing direct pathways for oxygen and moisture to reach the binder. This is especially critical in highway and airfield pavements, where maintaining surface integrity and waterproofing is essential for structural performance, durability and operational safety.

Understanding Durability in Asphalt Pavements

In the context of asphalt surfaces, durability refers to the ability of asphalt materials to retain their structural integrity, flexibility and surface characteristics under service conditions. A durable pavement maintains adequate rheology, cohesion and adhesion between the bitumen binder and aggregate throughout its service life, despite the combined effects of traffic loading and environmental exposure.

As asphalt pavements age, their properties gradually change through the process of oxidation. This occurs not only during production and laying but, more importantly, throughout their in-service life as the surface is continually exposed to air, water, ultraviolet radiation, temperature fluctuations and traffic loading. Over time, these influences cause the binder to harden, become brittle and lose its ability to resist cracking and deformation.

Influence of Air Voids in Asphalt Layers

Once in service, in-situ air voids within the asphalt mix become one of the most influential factors affecting durability. High or interconnected air voids allow oxygen and moisture to penetrate the surface layer more readily, accelerating oxidative ageing and binder hardening. This effect is particularly relevant in surface courses, which are directly exposed to environmental conditions, making them more vulnerable than lower layers.

Several practical and material factors can lead to higher-than-ideal air voids in compacted asphalt:

- Reduced bitumen content: Suppliers may marginally lower binder levels to meet mix design or cost targets, resulting in thinner binder films and increased void content.

- Increased recycled material content (RAP or RAS): Aged binder in recycled material may not fully blend with new binder, leading to poorer compaction and elevated voids.

- Adverse weather during paving: Low temperatures, high winds or moisture can limit compaction efficiency, trapping more air within the mix.

These factors can create more open-textured, permeable surface layers than intended. Over time, this results in accelerated oxidation, moisture ingress, ravelling, cracking and premature deterioration – effects that are particularly problematic for asphalt surfaces where performance, waterproofing and safety are critical.

Ageing of PMB and Conventional Binders

When a polymer modified bitumen (PMB) binder ages in service, the base bitumen oxidises and hardens, while the polymer component gradually degrades. The combined effect is a loss of elasticity, increased stiffness and reduced cohesion, ultimately making the surface layer more brittle and prone to cracking and ravelling.

For conventional paving-grade bitumen, the ageing and weathering processes follow a similar pattern – oxidation increases stiffness and brittleness while reducing ductility and adhesive strength. However, since conventional binders lack a polymer network, they tend to harden more uniformly, whereas PMBs experience a more complex transition as both the bitumen and polymer degrade.

Linking Durability to Performance

The rate of pavement ageing directly influences its functional performance. As the binder stiffens over time, asphalt loses flexibility, increasing the risk of cracking under thermal or traffic-induced stresses. Oxidation and moisture ingress further weaken the aggregate-binder bond, leading to stripping and ravelling.

On highways, this deterioration reduces ride quality, accelerates pothole formation and increases maintenance costs. Maintenance activities such as resurfacing can cause lane closures, diversions, and congestion, impacting road user satisfaction.

For airfields, pavement degradation affects surface integrity and operational safety, as broken pavement creates a Foreign Object Debris (FOD) risk. Any disruption during critical air traffic periods can have significant operational consequences, making careful scheduling and rapid, high-quality interventions essential.

To extend pavement life and maintain performance, proactive surface preservation treatments have become an increasingly valuable strategy. These treatments not only mitigate structural and functional deterioration but, when planned and executed efficiently, minimize disruption to both road and airfield users, helping to preserve service quality and safety.

The Role of Rhinophalt Asphalt Preservation

Rhinophalt works by penetrating deep into the asphalt surface, through microcracks and interconnected air voids to seal the pavement from within. This internal sealing action prevents the ingress of air and water, effectively stabilising the existing binder and reinforcing the aggregate–bitumen bond.

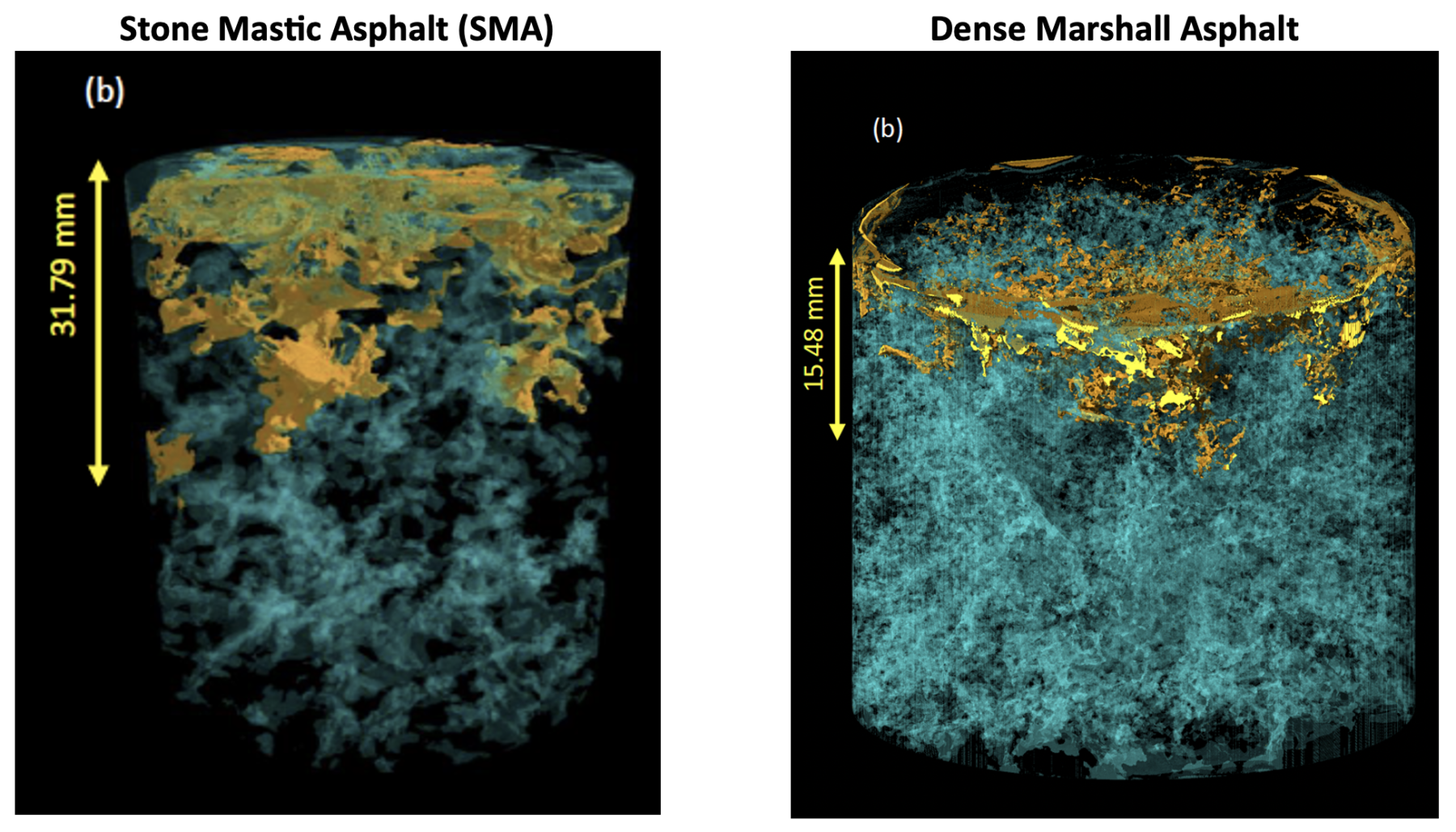

Independent X-ray CT scan analysis has demonstrated that Rhinophalt can penetrate to depths of up to 31.78 mm in Stone Mastic Asphalt (SMA) and 15.48 mm in Dense Marshall Asphalt. This deep penetration ensures that the treatment is not just a surface coating, but a genuine sub-surface preservation process that reinforces the pavement structure and significantly slows down the effects of oxidative ageing and weathering.

X-Ray CT scan illustrating the extent of RHiNOPHALT® penetration into the asphalt surface:

By forming a barrier against air and water, Rhinophalt helps maintain binder flexibility, reduces cracking and preserves surface integrity all without adversely affecting macrotexture or skid resistance. On highways and airfields, this translates to extended pavement life, fewer defects and reduced reactive maintenance.

Although much of the discussion has focused on waterproofing dense asphalt surfaces, Rhinophalt has also been successfully applied to open-graded and porous asphalt pavements. In these cases, the application rate is carefully adjusted to coat and protect the asphalt binder film within the high-void network without unduly affecting the material’s designed permeability or drainage performance. This adaptability allows Rhinophalt to deliver effective preservation across a wide range of asphalt types from SMA and Dense Asphalt surfaces to porous, noise-reducing layers, ensuring longer-lasting, sustainable pavement performance.

Summary

By directly addressing the primary mechanisms of asphalt surface ageing: oxidation, UV radiation, moisture ingress and subsequent binder degradation, Rhinophalt penetrative asphalt preservation provides a sustainable preventative maintenance solution that can extend pavement service life by several years. Its ability to seal interconnected voids and microcracks within the upper asphalt matrix enhances cohesion and significantly reduces the risk of cracking and ravelling, slowing the overall rate of deterioration.

With an ultra-low carbon footprint compared with traditional resurfacing or reconstruction, Rhinophalt offers asset managers a proven, environmentally responsible treatment aligned with decarbonisation and whole-life asset management objectives. In addition to substantial carbon and cost efficiencies, this approach minimises network disruption, delivering longer-lasting, higher-performing pavements while avoiding the operational and environmental impacts typically associated with major maintenance works.